Magnetic Drive Pumps

Safe, Reliable Industrial Solutions — Available from Stock

Techma GPM is a trusted partner in Italy and across Europe for the distribution of high-technology industrial pumps, with a wide range of products ready to ship to cut downtime and speed up new projects. Among the most in-demand solutions for complex applications, magnetic drive pumps are ideal when you need safety, reliability, and resistance to aggressive, toxic, or high-temperature liquids.

Available Types

Techma GPM supplies a broad range of magnetic drive pumps to meet requirements for flow rate, viscosity, precision, and chemical resistance. Key families include:

Magnetic Drive Centrifugal Pumps

Ideal for medium–high flows and low-viscosity liquids. Compact, corrosion-resistant construction, also available in ATEX versions.

Magnetic Drive Gear Pumps

Perfect for viscous liquids, precise dosing, and OEM applications. Available with Micropump technology and AC/DC variants, including ATEX options.

Solutions Designed for Industry Professionals

- No fluid leakage

- Ideal for ATEX environments

- Suitable for OEM systems and complex industrial processes

- Fast delivery from stock for many standard models

Benefits of Magnetic Drive Pumps

- Maximum safety: no fluid escape, even with hazardous or toxic liquids.

- Long-term reliability: no wear-prone mechanical seals.

- Reduced maintenance: fewer spare parts, less downtime.

- Chemical resistance: materials compatible with aggressive, corrosive fluids.

- Quiet operation: suitable for noise-sensitive environments.

- High energy efficiency: optimized performance with magnetic coupling.

- Thermal resistance: models available for temperatures up to 300 °C.

- Immediate availability — fast shipping from our Italy hub for many standard models

Applications by Industry

Magnetic drive pumps are used across many industries, with specific advantages for each context:

- Chemical: safe handling of strong acids such as sulfuric or hydrochloric acid, including ATEX areas. See also pumps for corrosive and acidic liquids.

- Pharmaceutical: sterile transfer of solvents and reagents, no lubricant contamination.

- Food & beverage: handling CIP liquids and delicate fluids with full hygiene.

- Water treatment: dosing of substances such as sodium hypochlorite or ammonia.

- Electronics: transfer of ultra-pure liquids in cleanrooms, with no contamination risk.

- Oil & Gas: handling thermal oil at elevated temperatures (>300 °C). See also our industrial cooling solutions.

Why Choose Techma GPM

Wide range of models in stock

Direct technical support from specialists

Custom solutions for OEMs and special applications

Distribution of leading brands such as Micropump and Sanso

Contact Us

Techma GPM is your partner for high-performance liquid handling. Get in touch for tailored technical advice and to find the best model for your needs.

Write to us nowRecommended Resources

For a deeper technical dive or to assess specific solutions, we recommend:

Flammable liquids pumps – ATEX solutions

Industrial micro-dosing pumps

Cooling pumps for OEM environments

Precision positive displacement pumps

Micropump technology – Suction Shoe

FAQ – Magnetic Drive Pumps

What are the main advantages of a magnetic drive pump?

Hermetically sealed operation with no leaks, reduced maintenance, strong chemical and thermal resistance, and greater safety with hazardous fluids.

Are magnetic drive pumps suitable for ATEX environments?

Yes, Techma GPM supplies ATEX-certified models for use in potentially explosive atmospheres.

Which industries use these pumps most often?

Chemical, pharmaceutical, food & beverage, water treatment, electronics, oil & gas, and OEM.

Can they handle high-temperature liquids?

Yes, some models are designed to operate up to 300 °C.

Does Techma GPM have magnetic drive pumps available from stock?

Yes, many models are available immediately from our warehouse to minimize plant downtime.

Can I request customized solutions?

Absolutely. We offer tailor-made configurations for OEMs and special applications.

What is a Magnetic Drive Pump?

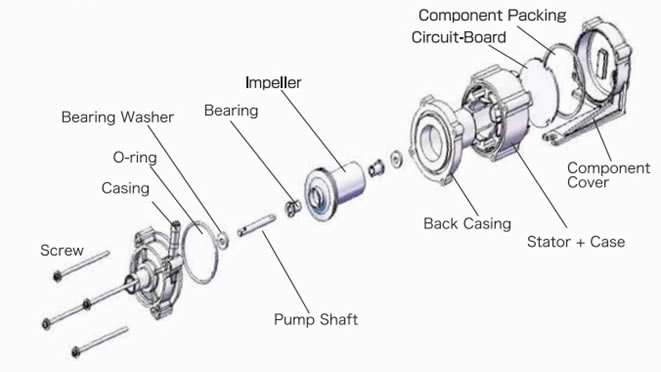

A magnetic drive pump uses a magnetic coupling to transfer power from the motor to the impeller, eliminating the need for a traditional mechanical seal.

This enables:

- Hermetic, leak-free operation

- Lower maintenance

- Improved operational safety, even with hazardous fluids

The system features two permanent magnets (one on the motor shaft, one on the internal impeller) separated by a containment shell that preserves the integrity of the pumped fluid, preventing contamination or emissions to the outside.

For highly critical industrial applications, you can also consider alternatives such as pumps for aggressive chemicals and solvents, or custom OEM solutions.

How Magnetic Drive Pumps Work

The operating principle is straightforward. The rotor consists of a shaft and a pair of permanent magnets that generate a magnetic field. The internal rotor is housed within a casing compatible with the pumped liquid (the pump head). The internal shaft is connected to a magnet located at the rear of the head, inside the “containment cup,” fully isolated from the exterior. There is only one static seal (typically an O-ring), for which you must verify chemical compatibility.

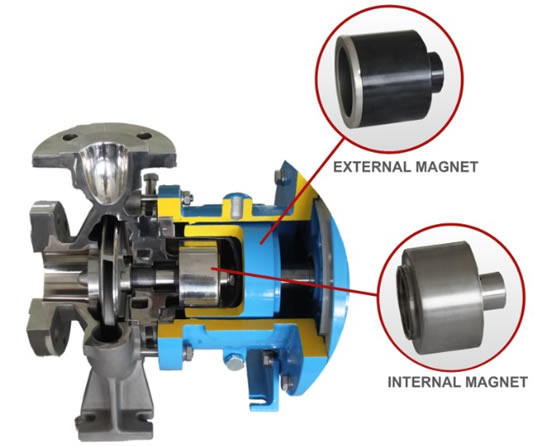

The internal magnet can then be driven in two ways:

For smaller pumps, a “canned” brushless DC motor configuration is possible, where the pump’s containment cup is inserted within the motor windings. These windings generate a rotating magnetic field that couples directly to the internal magnet, transmitting motion. Alongside the benefits of magnetic drive, this arrangement significantly reduces the overall pump + motor size — crucial in some applications.

Alternatively, motion is transmitted by an external magnet mounted directly on the motor shaft. The magnetic field between the two magnets transfers torque from outside to inside the pump.