Magnetic drive pumps

Techma GPM is a point of reference of the Italian and European market for the distribution of high-tech pumps. In particular, one of the fastest growing sectors is undoubtedly the magnetic drive pumps one, which represent an ideal solution for many applications.

Magnetic drive pumps: an ideal solution for many application

Mag drive pumps use a pair of magnets to transfer the rotation from the motor to the pump head. The magnets generate a magnetic field which rotates the pump shaft. This system eliminates the need of a mechanical seal, reducing the risk of liquid leaks.

Magnetic drive technology was developed in the 1940s, but only in recent decades it become widespread in industry thanks to the many advantages it offers. In addition to reducing liquid losses, magnetic drive pumps are also safer, as they eliminate the risk of contamination of the liquid by seals, which could deteriorate over time. Also, since there are no moving parts in contact with each other, maintenance is greatly reduced, resulting in lower costs.

Magnetic drive pump applications

Mag drive pumps are used in a wide range of applications. For example, in cooling circuits where both the loss of liquid to the outside is not acceptable and any contamination by fragments of mechanical seal would affect the efficiency of the process. But also in industrial applications, including the transfer of aggressive, toxic or corrosive liquids. As there are no metal parts in contact with the liquid, the pump is resistant to corrosion and therefore ideal for use in harsh environments. Magnetic drive pumps are also used in applications where the risk of leakage is unacceptable, such as in the food, pharmaceutical and chemical industries.

This type of pump is therefore definitely preferable to traditional sealed pumps when you are looking for reliability, safety and durability.

Furthermore, thanks to their conformation, they can be used for applications with liquids at extremely high temperatures: up to approximately 200°C.

How magnetic drive pumps work

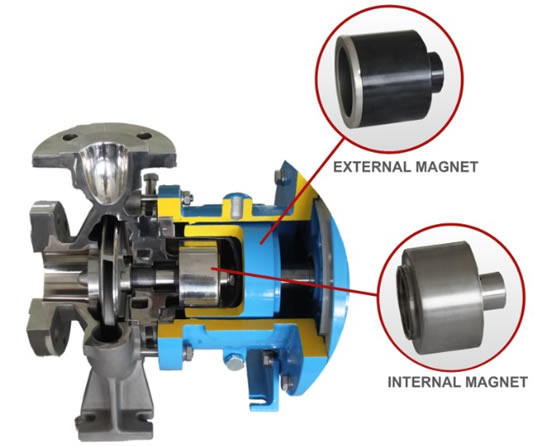

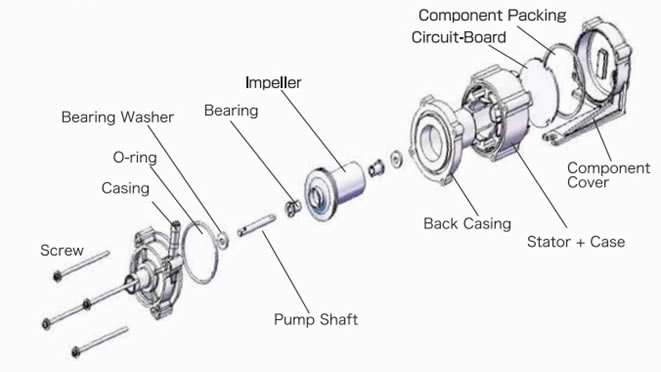

The operation of magnetic drive pumps is very simple. The rotor consists of a shaft and a pair of permanent magnets, which generate a magnetic field. The shaft inside the pump is connected to the internal magnet, this magnet is located inside the pump head and positioned in the rear part called the "cup" completely isolated from the outside. There is a single static seal (generally an O-ring) for which only chemical compatibility needs to be considered.

The internal magnet can then be operated with rotary motion by two possible solutions:

- Coupled to an external magnet which is placed directly on the motor shaft. The magnetic field between the two magnets ensures the transmission of motion from the outside to the inside of the pump.

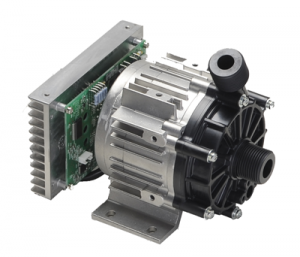

- For the smaller pumps it is possible to configure a canned brushless DC motor in which the pump cup is inserted inside the motor windings. These windings generate a rotating magnetic field which connects directly to the internal magnet thus ensuring motion transmission. Obviously, this solution, in addition to all the advantages of magnetic drive, guarantees a significant reduction in the size of the pump + motor assembly, an important feature in some cases.

The magnets used can be made of various materials depending on the magnetic torque required by the application. Generally, the higher the differential pressure in the application, the more magnetic torque will be required. It starts from standard ferrite magnets for applications with minimum pressures up to using rare earth magnets such as samarium-cobalt or neodymium to ensure high performance.

The movement of the liquid takes place thanks to the difference in pressure between the suction chamber and the delivery chamber. As the rotor rotates, it creates a low pressure zone in the suction chamber, which lets the liquid enter. As the rotor turns towards the discharge chamber, the liquid is pushed out. The pump can be precisely controlled by varying the motor speed or the diameter of the delivery orifice.

Mag drive pumps are available in several configurations, including centrifugal pumps and positive displacement pumps. Techma gpm is distributor for Italy and Europe of various types such as:

The advantages of magnetic drive pumps

Here is a summary of the benefits of mag drive pumps:

- they do not require a mechanical seal, which is a component that can cause wear and fluid leakage problems.

- they are safer than mechanically sealed pumps, because there is no risk of contamination of the fluid by the mechanical seal itself.

- they require no internal lubrication or cooling, making them ideal for use in applications that require thorough cleaning and where no contamination of the fluid from the lubricating/cooiling oil can occur.

- Mag drive pumps are quieter than shaft seal pumps, making them suitable for use in noise sensitive environments.

- They need much less maintenance as they do not have a mechanical seal which tends to wear out over time. This translates into cost savings and a lower incidence of plant downtime due to ordinary and extraordinary maintenance.

- they are able to withstand high temperatures and corrosive media, making them suitable for use in demanding industrial applications.