Pumps for Acids and Corrosive Liquids

Companies involved in the construction or assembly of industrial plants often need to handle acids and corrosive liquids with maximum safety and efficiency. Choosing the right pump is essential to ensure plant longevity, prevent damage to components, and maintain high safety standards.

Application Sectors and Use Cases

Pumps for acids and corrosive liquids are used across a range of industrial sectors, including:

Chemical Industry

Handling of acids and aggressive solutions in production processes.

Water Treatment

Dosing and transferring chemicals for purification.

Pharmaceutical Industry

Handling acidic solutions in the synthesis of active ingredients.

Electroplating and Metallurgy

Used in pickling baths and surface finishing processes.

Food Industry

Employed in processes requiring the handling of corrosive substances for cleaning and sanitization.

Explore the best solutions for your business and choose the pump that best fits your operational needs.

Acid Pumps

Go to section

Plastic Magnetic Drive Pumps

Our centrifugal pumps are ideal for managing and transferring acids, thanks to magnetic drive technology that eliminates mechanical seals—which are prone to wear and potential leaks over time. These pumps offer excellent efficiency and long-term durability, enabling continuous operation with minimal maintenance and avoiding costly plant downtime.

Plastic Acid Pumps

Plastic pumps are an excellent solution for handling acids due to their high chemical resistance and lightweight materials. Available options include centrifugal and magnetic drive pumps made from materials such as polypropylene (PP), polyvinylidene fluoride (PVDF), and polytetrafluoroethylene (PTFE).

Hydrochloric Acid Pump

Hydrochloric acid is highly aggressive and requires pumps made from specific materials like PVC, PP, or PVDF. Pumps for hydrochloric acid must ensure a hermetic seal to prevent hazardous leaks and corrosion of components.

Nitric Acid Pump

Nitric acid is known for its high reactivity, making it essential to use pumps built with highly resistant materials such as PTFE or PVDF. These pumps must provide maximum safety and long-lasting performance

Our Solution:

Technical specifications and construction features

CM MAG P Series

Body – impeller and magnet : PP or PVDF

Shaft and thrust bearing : PTFE / Graphite

Shaft bearings : PTFE / Graphite

“O” ring : Viton – EPDM

Flow rate : up to 20 m3/h Head : up to 18 m

Liquid temperature : fino a 90 C°

Specific gravity of the liquid : up to 1.9 kg / dm3

System pressure : PN 6

To ensure safe and completely sealed transfer of acids and corrosive substances, consider our magnetic drive pumps — seal-free and ideal for handling hazardous fluids.

Magnetic centrifugal pumps provide a safe and leak-free solution for the continuous transfer of highly corrosive acids.

Diaphragm Pumps for Acids

Diaphragm pumps are ideal for transferring acids thanks to their ability to operate safely without the risk of leaks. They offer high corrosion resistance and can be used in a wide range of industrial applications.

1/2” Double Diaphragm Air-Operated Pumps

| Flow Rate | up to approx. 65 l/min |

| Pumped Fluid Temperature | up to 93?°C |

| Suction Lift | up to 7.9 m |

| Suspended Solids Diameter – SPHERE | up to 1.6 mm |

| Suspended Solids Diameter – MAX PASS | up to 9.5 mm |

| Compressed Air Inlet | 1/4” threaded |

| Pipe Connections | 1/2” threaded |

| Maximum Noise Level (with silencer) | 83 dbA |

3/4” Double Diaphragm Air-Operated Pumps

| Flow Rate | up to approx. 65 l/min |

| Pumped Fluid Temperature | up to 93 °C |

| Suction Lift | up to 7,9 m |

| Suspended Solids Diameter | up to 3,2 mm |

| Compressed Air Inlet | 1/4” threaded |

| Pipe Connections | 3/4” threaded |

| Maximum Noise Level (with silencer) | 83 dbA |

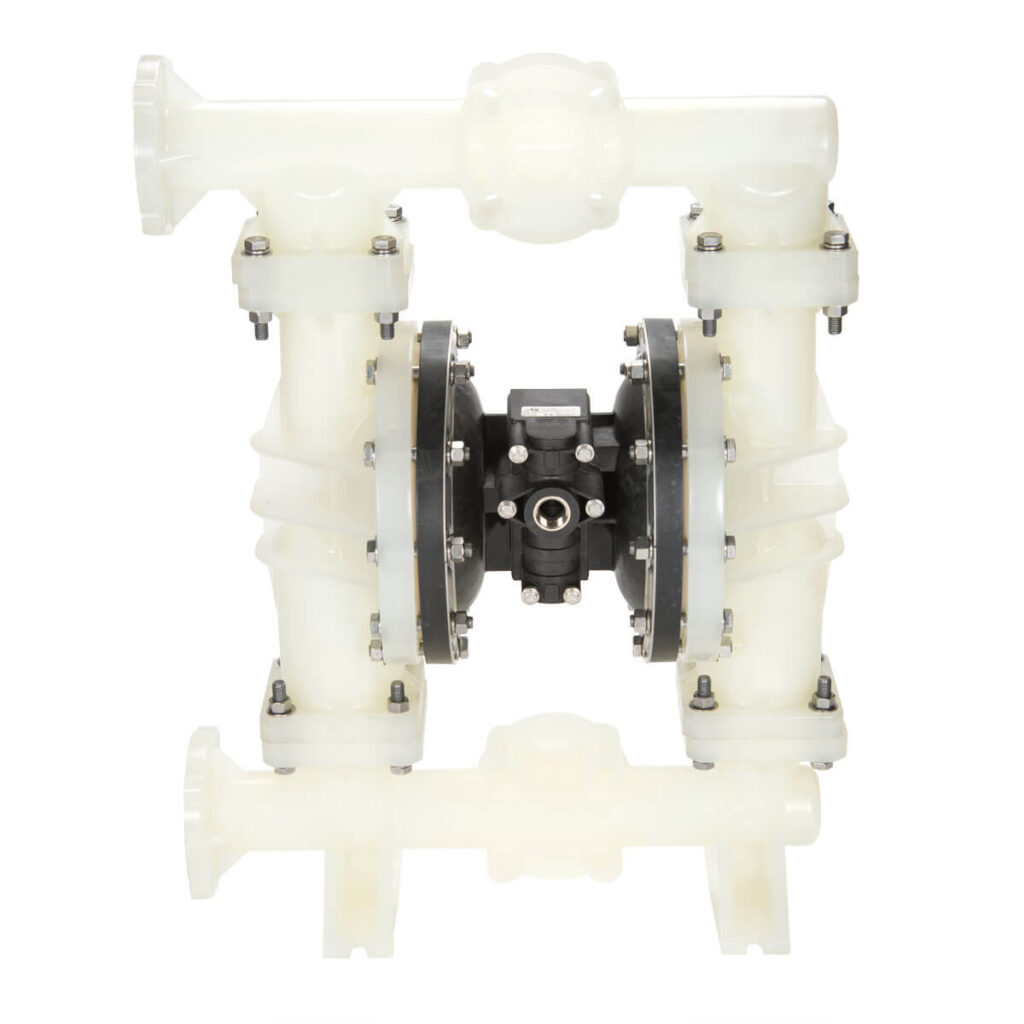

2” Double Diaphragm Air-Operated Pumps

| Flow Rate | up to approx. 680 l/min |

| Pumped Fluid Temperature | up to 93 °C |

| Suction Lift | up to 7,9 mt |

| Suspended Solids Diameter | up to 6,4 mm |

| Compressed Air Inlet | 3/4” threaded |

| Pipe Connections | 2″ Threaded DIN/ANSI – Tri Clamp 2 1/2” |

| Maximum Noise Level (with silencer) | 78 dbA |

1 1/2” Double Diaphragm Air-Operated Pumps

| Flow Rate | up to approx. 492 l/min |

| Temperatura del fluido pompato | up to 93 °C |

| Suction Lift | up to 7,9 mt |

| Suspended Solids Diameter | up to 6,4 mm |

| Compressed Air Inlet | 3/4” threaded |

| Pipe Connections | 1 1/2″ Threaded DIN/ANSI – Tri Clamp 2” |

| Maximum Noise Level (with silencer) | 78 dbA |

Pompe pneumatiche a doppia membrana da 1”

| Flow Rate | up to approx. 155 l/min |

| Pumped Fluid Temperature | up to 93 °C |

| Suction Lift | up to 7,9 m |

| Suspended Solids Diameter | up to 6,4 mm |

| Suspended Solids Diameter – MAX PASS | up to 19 mm |

| Compressed Air Inlet | 1/4” threaded |

| Pipe Connections | 1″ Threaded, 1″ flangiati DIN/ANSI e Tri Clamp 1 1/2” |

| Maximum Noise Level (with silencer) | 80 dbA |

1” Double Diaphragm Air-Operated Pumps

| Flow Rate | up to approx. 16 l/min |

| Pumped Fluid Temperature | up to 93 °C |

| Suction Lift | up to 7,9 m |

| Suspended Solids Diameter | up to 1,6 mm |

| Compressed Air Inlet | 1/4” threaded |

| Pipe Connections | 1/4” threaded |

| Maximum Noise Level (with silencer) | 86 dbA |

Pompe pneumatiche a doppia membrana da 3/8”

| Flow Rate | up to approx. 34 l/min |

| Pumped Fluid Temperature | up to 93 °C |

| Suction Lift | up to 7,9 mt |

| Suspended Solids Diameter – SPHERE | up to 1,6 mm |

| Suspended Solids Diameter – MAX PASS | up to 6,4 mm |

| Compressed Air Inlet | 1/4” threaded |

| Pipe Connections | 3/8” threaded |

| Maximum Noise Level (with silencer) | 86 dbA |