Micropump AC

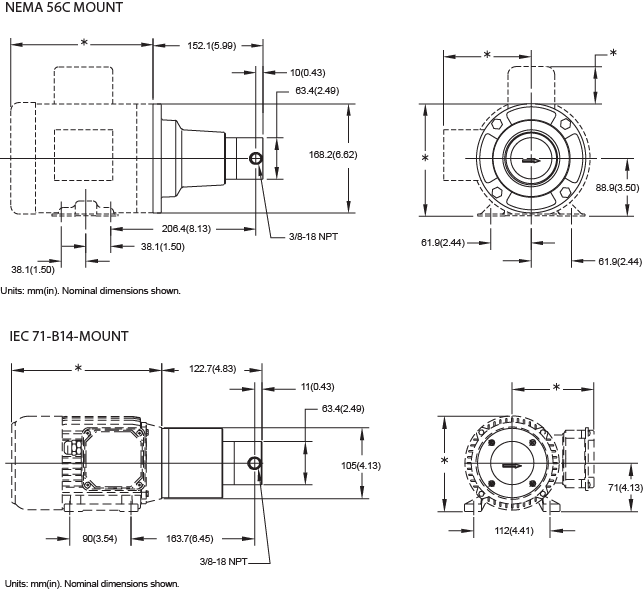

The Micropump AC magnetic gear micropumps are positive displacement pumps designed for applications where reliability, precision, and compactness are essential.

Equipped with an AC motor and featuring a “suction shoe” design, these pumps ensure accurate, continuous microdosing, long operational life, and complete leak-free performance.

Techma GPM is the official Micropump distributor for Italy and Europe.

We provide technical support, custom configurations, and OEM integration consulting to meet specific application requirements.

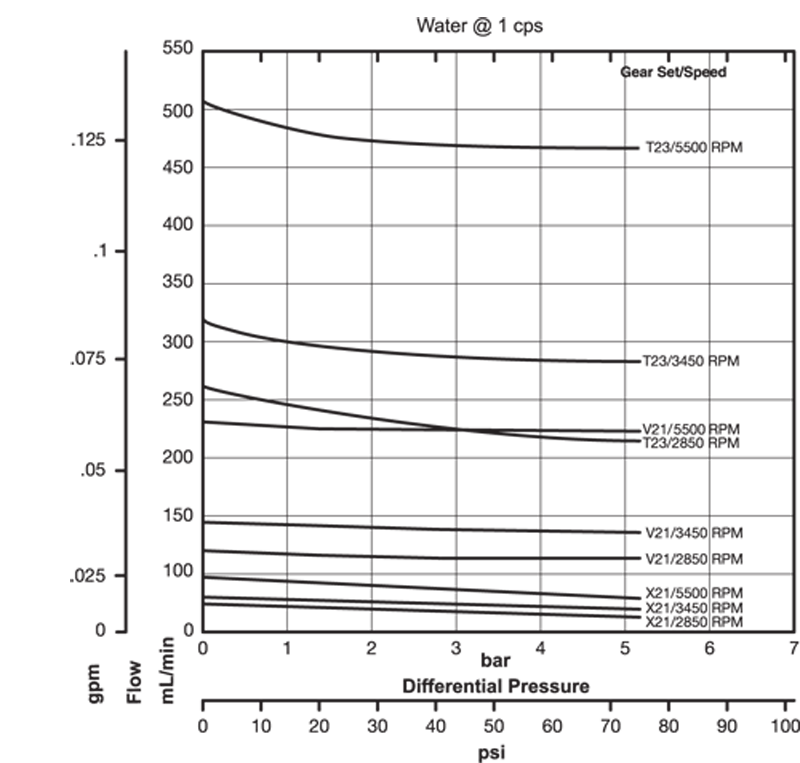

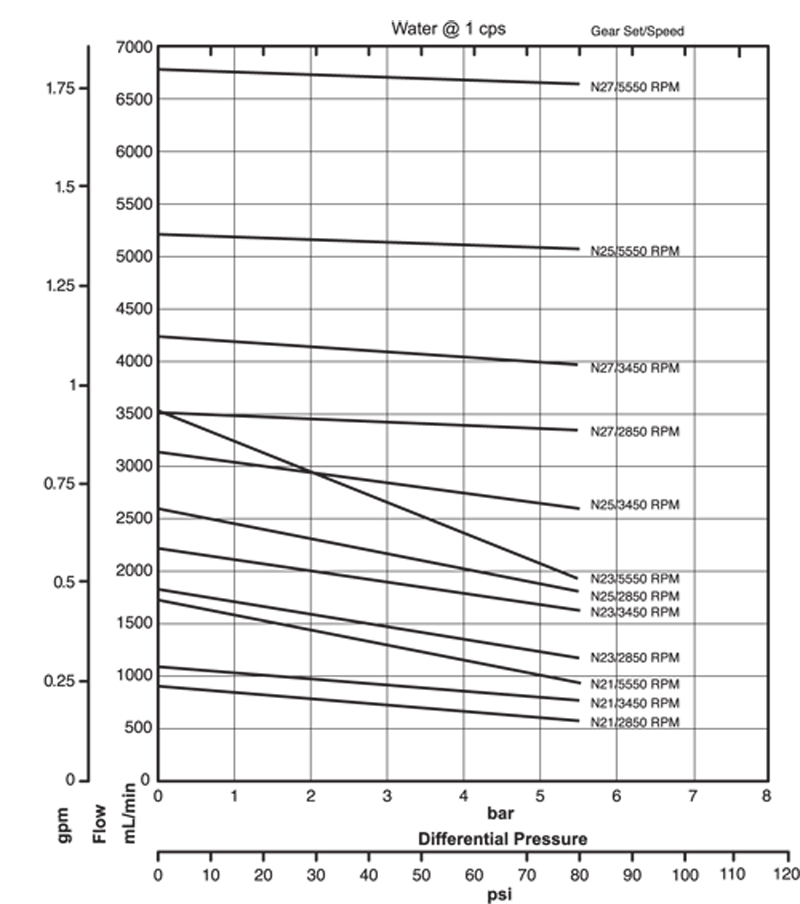

Serie GA

The GA magnetic drive gear pumps series provide a precise flow without pulsations, ideal for continuous and discrete dosages and micro dosages. Thanks to the “suction shoe” designed by Micropump, the GA series pumps automatically compensate the wear, this feature reduces leakage and ensuring a longer pump life. The GA pumps are available in a wide range of materials and configurations such as SS316 for the body, PPS or PEEK for the gears and PTFE, EPDM or Viton for the static sealing O-ring.

| Flow rate (min) | Flow rate (max) | Differential pressure (max) |

System pressure |

|---|---|---|---|

| 10 mL/min | 250 mL/min | 5.2 bar | 21 bar |

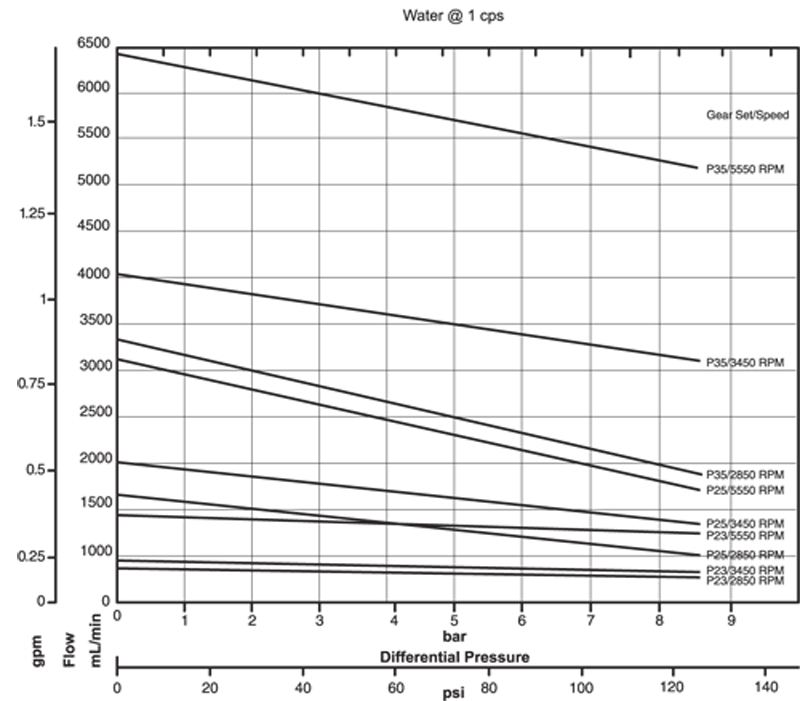

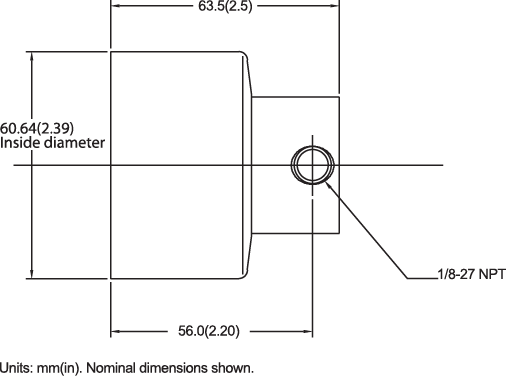

Serie GB

The GB magnetic drive gear pumps series provide a precise flow without pulsations, ideal for continuous and discrete dosages and micro dosages. Thanks to the “suction shoe” designed by Micropump, the GB series pumps automatically compensate the wear, this feature reduces leakage and ensuring a longer pump life. The GB pumps are available in a wide range of materials and configurations such as SS316 for the body, PPS or PEEK for the gears and PTFE, EPDM or Viton for the static sealing O-ring. Available in standard or custom configurations, the GB series pumps, with their compact dimensions, offer the flexibility to meet a wide range of applications.

| Flow rate (min) | Flow rate (max) | Differential pressure (max) |

System pressure |

|---|---|---|---|

| 200 mL/min | 3 L/min | 8.6 bar | 21 bar |

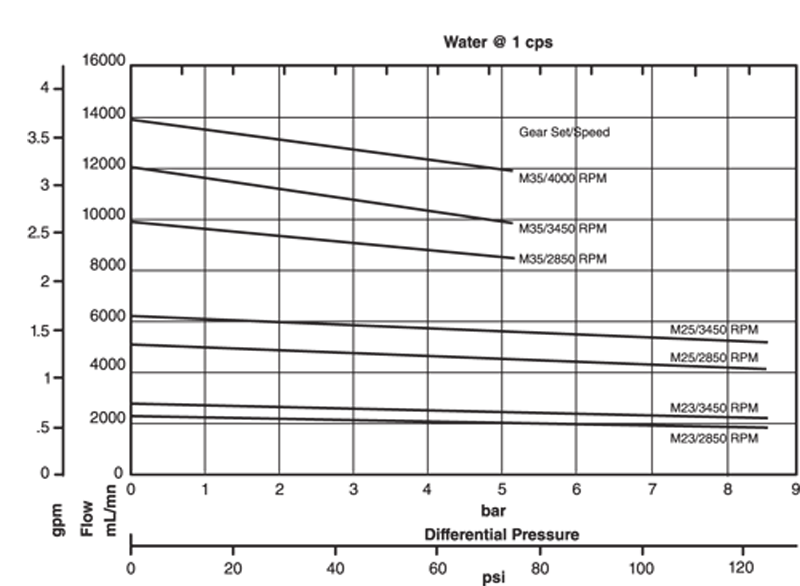

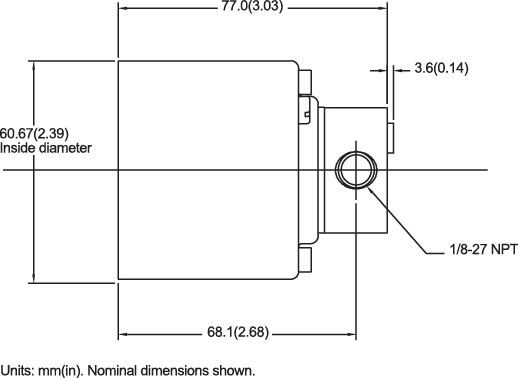

Serie GC

The GC magnetic drive gear pumps series offer high performance, a pulsation-free flow, extremely compact dimensions and the ability to withstand high system pressures up to 103 bar (1500 psi). The GC series pumps are perfect for demanding applications and are available in a wide range of materials and configurations such as SS316 for the body, PPS or PEEK for the gears and PTFE, EPDM or Viton for the static seal O-ring.

| Flow rate (min) | Flow rate (max) | Differential pressure (max) |

System pressure |

|---|---|---|---|

| 500 mL/min | 10 L/min | 8.6 bar | 103 bar |

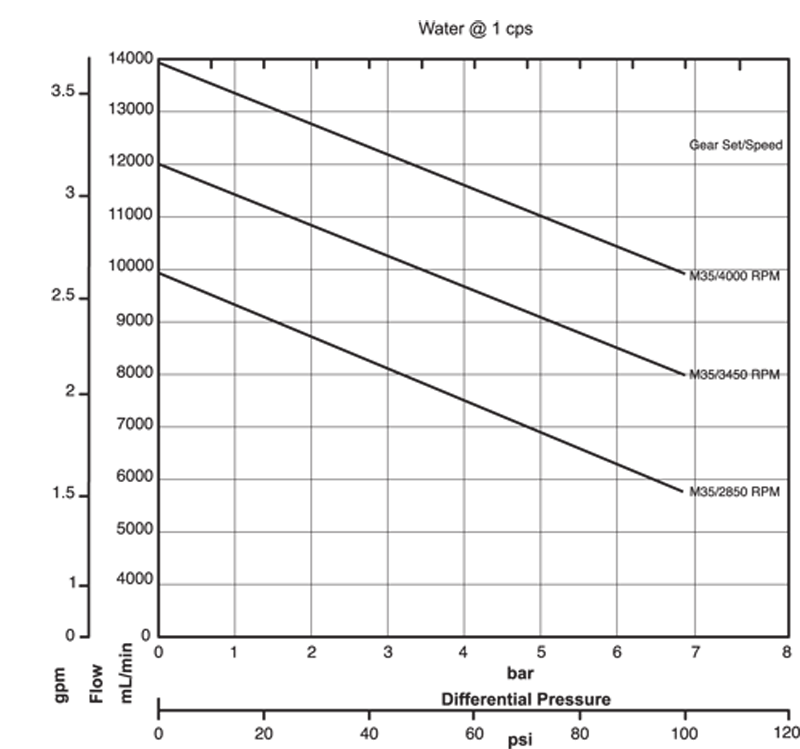

Serie GD

The GD magnetic drive gear pumps series resist high system pressures up to 103 bar (1500 psi) and these pumps are the only ones that can have metal gears. To underline the high chemical resistance, ease of maintenance and a wide range of options that make the GD series pumps the right choice for a wide variety of applications.

| Flow rate (min) | Flow rate (max) | Differential pressure (max) |

System pressure |

|---|---|---|---|

| 2 L/min | 9 L/min | 6.9 bar | 103 bar |

Serie GJ

The GJ magnetic drive gear pumps series offer exceptional performance in pumping liquids in applications where great precision is required, whether it is a dosage or a recirculation. These pumps are extremely compact and they are the best solution for applications where leakage is not tolerated. The GJ series pumps are available in a wide range of versions, as well as in standard and OEM configurations.

| Flow rate (min) | Flow rate (max) | Differential pressure (max) |

System pressure |

|---|---|---|---|

| 250 mL/min | 3.5 L/min | 5.5 bar | 21 bar |

Discover our complete range of gear pumps.

Benefits of Magnetic Gear Micropumps – AC Series

- Accurate, continuous dosing without pulsations

- “Suction shoe” technology for automatic wear compensation

- High chemical and mechanical resistance

- Reliable AC motor designed for continuous operation

- Ideal for food, chemical, and environmental applications

- Perfect for microdosing of even highly viscous fluids

- Available in OEM versions and for integration into analytical systems

Industries and Applications

- Medical and laboratory dosing (e.g. pharmaceuticals, reagents)

- Food industry (e.g. flavorings, additives)

- Chemical sector: solvents, acids, corrosive substances

- OEM: compact systems for precision dosing

- Water treatment and environmental dosing systems

- Micropumps for analytical instrumentation and reagent dosing

- Dosing of viscous or chemically aggressive fluids

- Microdosing solutions for industrial, environmental, and food applications

Contact us

Techma GPM provides dedicated technical support, customized configurations, and professional customer service to ensure optimal long-term performance.

Get in touchFrequently Asked Questions

What’s the difference between Micropump AC and DC?

AC pumps are ideal for continuous operation in fixed installations, while DC models suit portable or energy-efficient systems.

Are AC pumps suitable for the food industry?

Yes, many versions comply with hygiene requirements and can dose flavorings, colorants, and additives.

Can the dosing rate be adjusted?

Yes, by controlling frequency or adjusting inlet pressure and downstream valves.

What type of positive displacement pumps are Micropump AC models?

Micropump AC units are magnetic gear positive displacement pumps, designed for precise microdosing of liquids through magnetic coupling with no direct contact between motor and fluid.

You are here: