CM MAG Centrifugal Pumps

Plastic or Stainless Steel for Acids and High Temperatures

CM MAG magnetic drive centrifugal pumps are engineered for chemical resistance, leak-tight operation and continuous reliability. Available in molded plastic (PP or PVDF) or investment-cast stainless steel (AISI 316), they are ideal for handling acids, solvents and high-temperature fluids.

Thanks to their sealless magnetic construction, they are an excellent choice wherever zero leakage, operator safety and long service life are required.

Available Models

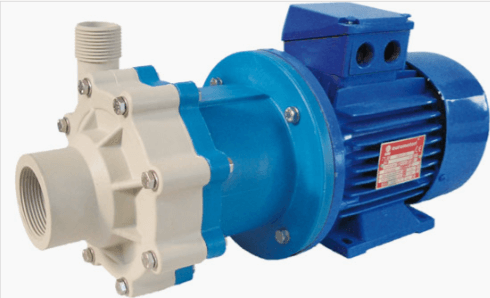

CM MAG P Series

Plastic (PP / PVDF)

- Casing, impeller, magnet: PP or PVDF

- Shaft and bearings: PTFE / graphite

- O-rings: Viton or EPDM

- Flow rate: up to 20 m³/h

- Head: up to 18 m

- Fluid temperature: up to 90°C

- Max pressure: PN 6

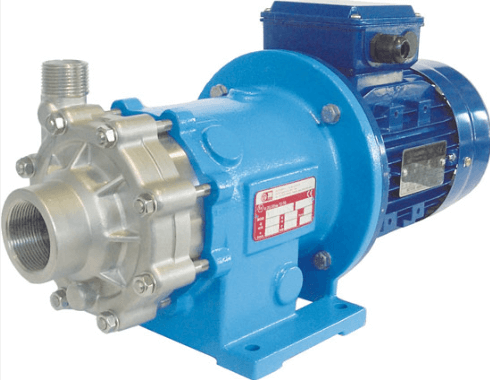

CM MAG M Series

Stainless Steel AISI 316

- Casing, impeller, magnet: 316 stainless steel

- Bearings: Silicon carbide

- O-rings: Viton

- Flow rate: up to 40 m³/h

- Head: up to 35 m

- Fluid temp.: -40°C to +200°C

- Max pressure: PN 16

Key Features

- Sealless magnetic drive

- Available in plastic (PP / PVDF) or AISI 316 stainless steel

- Bearings in PTFE, graphite or silicon carbide

- Versions for liquids up to 200°C and 1.9 kg/dm³

- High reliability and pressure up to PN 16

Typical Applications

- Handling and transfer of highly corrosive acids

- Chemical and electroplating industry

- ATEX plants with flammable fluids

- High-temperature cooling with thermal oil

Contact us

Techma GPM is your trusted partner for plastic and stainless-steel centrifugal pumps in critical applications. We provide technical support, tailored solutions and certified products from leading international manufacturers.

Write to us nowFrequently Asked Questions

Can CM MAG pumps be used with strong acids?

Yes, the PVDF version is designed to resist highly corrosive fluids.

What’s the difference between CM MAG P and M?

The P is plastic for acids up to 90°C; the M is stainless steel for higher temperatures and pressures.

Are they suitable for ATEX areas?

On request, we can offer configurations compliant with ATEX requirements.

You are here: