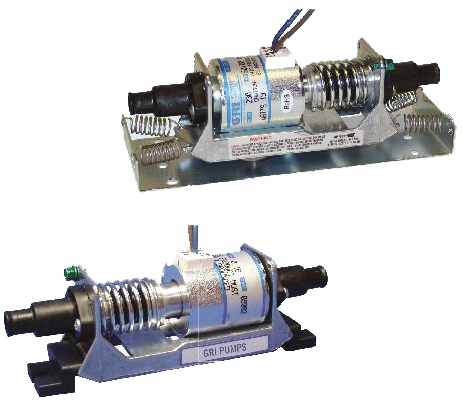

Oscillating

The oscillating pumps of Gorman Rupp are machines suitable for the transfer and dosage of even aggressive liquids. The operation is based on the alternative rectilinear movement induced in a body immersed in an alternating magnetic field, generated by a toroidal magnet crossed by an alternating voltage cut in the negative half-wave. During the positive phase of the voltage, the magnetic field allows the pumping element, that we will call “impeller”, to move from the suction to the discarge and then to operate the fluid suction phase, through a optimized valve system. At the passage of the voltage wave in the zero point, a diode interrupts the power supply, and therefore the impeller, which translating during the suction phase has loaded a spring, reverses the direction and returning to the initial position, operates the phase of fluid delivery. The suction and delivery cycles follow one another in synchrony with the frequency available on the supply network and then 50 or 60 times per second, for networks fed at the frequency of 50 or 60 Hz. Available in a wide variety of models, with impeller spring reel, helical or helical type, mounted on rubber or spring anti-vibration mountings, and valves also with wide passage for dirty liquids, these machines have numerous advantages compared to traditional machines , advantages that we can summarize here: – Minimum pulsation of the pumped fluid, thanks to the speed of the work cycle – Minimum power consumption – Maximum speed of starting and stopping, thanks to the small moving masses – Minimum weight and compact size – Possibility to run dry – No metal parts in contact with the pumped fluid